Loading . . .

No matches found

Essex Brownell offers customers a collection of over 100,000 SKUs from 450+ premier suppliers, but one product has been our cornerstone for over 90 years: magnet wire.

Known for its incredible versatility and reliability, magnet wire is an essential component across nearly every industry we serve from aerospace to energy and beyond.

In this blog series, we’ll be highlighting the various applications magnet wire has for the industries we serve including:

Industrial

Energy

Motor & Motor Repair

Commercial & Residential

Electronics

Military & Aerospace

Mobility

Throughout this series we will explore our product offerings and how they work alongside magnet wire to drive the markets we serve forward. First, however, we want to answer two very important questions:

What is magnet wire?

What is magnet wire used for?

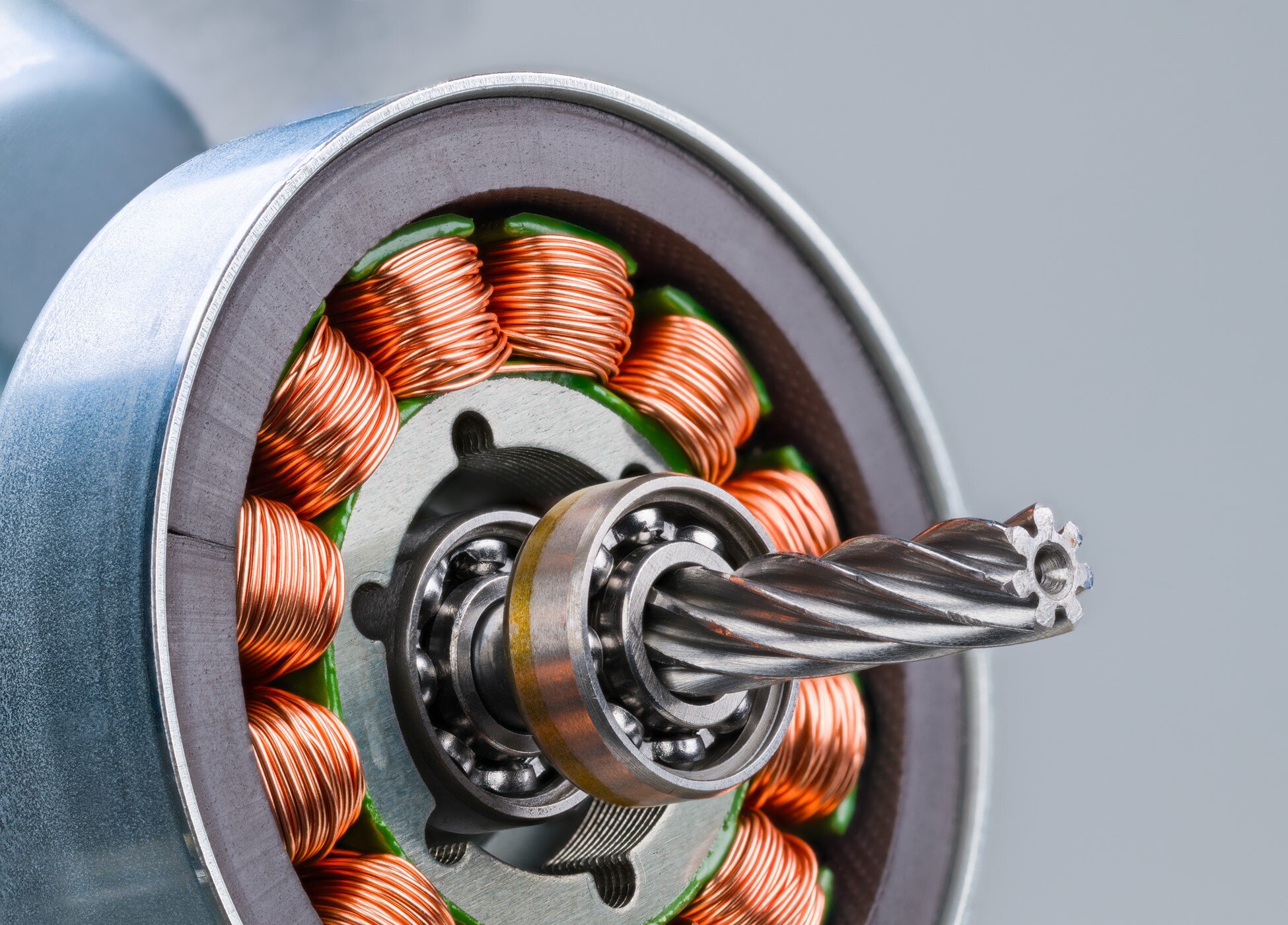

Google AI defines magnet wire, also known as enameled wire or winding wire, as “an insulated copper or aluminum wire used to create electromagnetic fields.”

That doesn’t even begin to paint a picture of what magnet wire is and how it’s used in nearly everything we touch and interact with every day.

Whether copper or aluminum, magnet wire is wire with an insulated coating over the metal. This insulation is used to prevent short circuiting when the wire is wound into coils while still allowing electrical current to move through it.

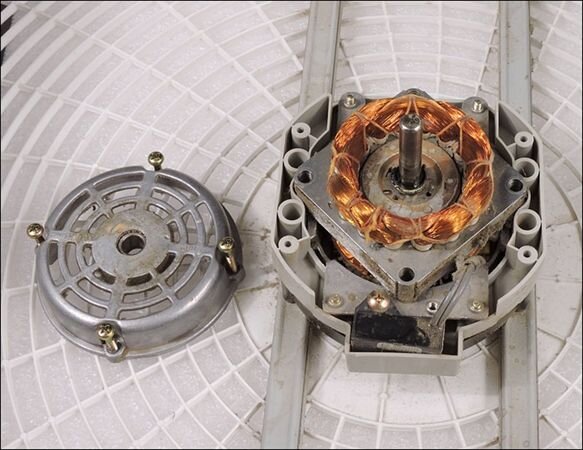

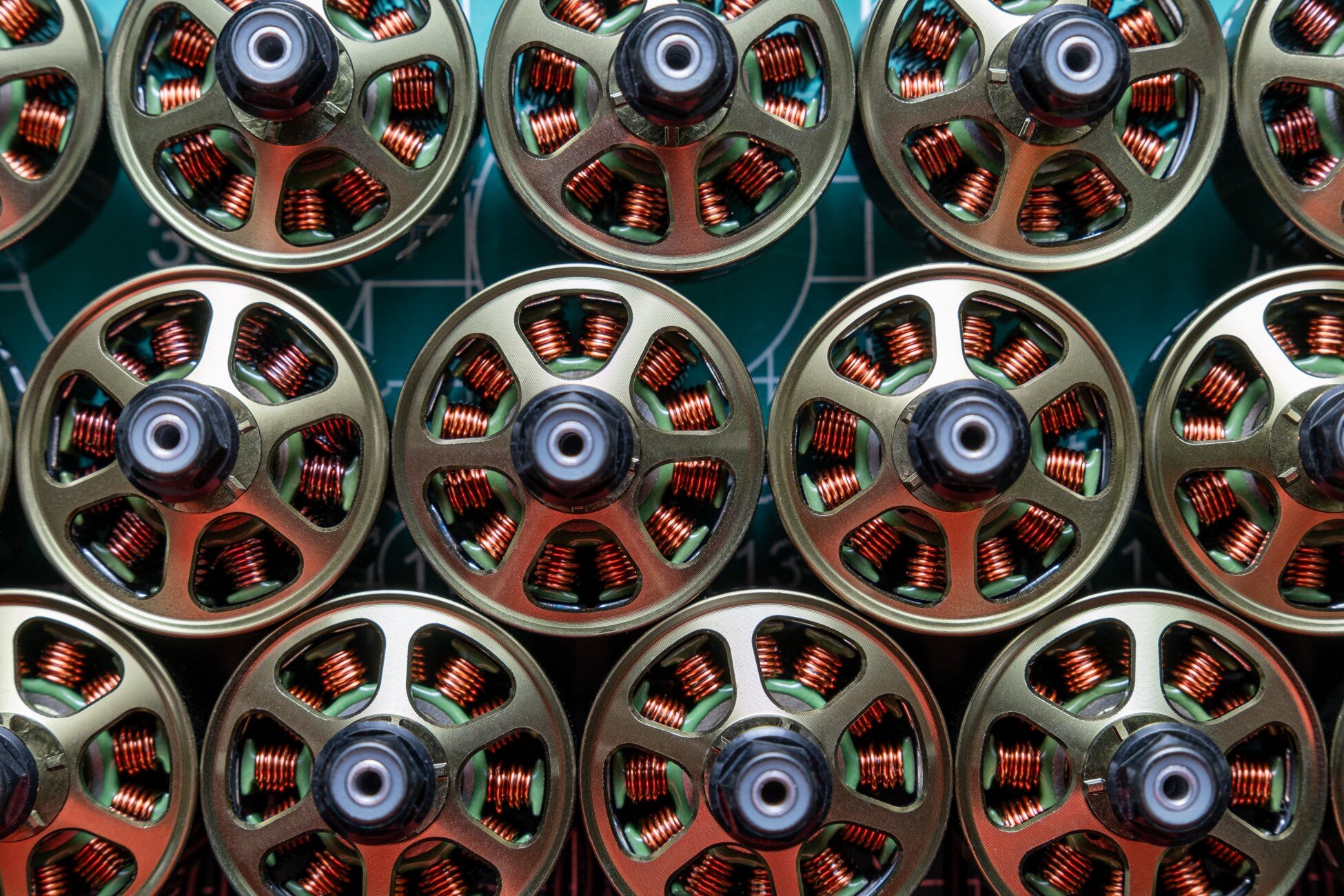

These coils are seen in many household and industrial applications like fan motors for appliances as small as blenders or vacuum cleaners, generators, audio equipment like speakers or headphones, and transformers. No matter where it’s found, magnet wire allows the conversion of electrical energy to mechanical energy and the storing of electrical energy as a magnetic field.

Magnet wire as we know it today traces back to the early 20th century when American inventor George A. Jacobs revolutionized the industry by developing an enamel insulation process for copper wire.

This new process replaced the bulky cotton fiber wrapping previously used, offering a more durable, precise, and cost-effective solution. With this advancement, Jacobs started the Dudlo Company in Fort Wayne, IN, quickly taking over the market.

In 1927, Dudlo merged with two other companies to form General Cable Corporation. Two years later, in 1929, the company produced the first American-made 75,000-volt submarine cable for the Delaware River Crossing. At 4,050 feet with no joints, it was the longest of its kind at the time.

In 1930, Addison E. Holton, then director of Anaconda Wire and Cable, brought several businesses together to form Essex Wire Corporation. One of his first major moves was acquiring Ford Motor Company’s wire assembly operations. By 1936, Essex had grown exponentially and acquired the former Dudlo Manufacturing Corporation building, further cementing its presence in the industry.

During World War II, Essex played a critical role in the war effort by manufacturing field telephone wire, transformers for the Army Signal Corps, and wire harnesses for B-24 Bombers. After the war, the demand for magnet wire surged as electric appliances became staples in every American household. Refrigerators, stoves, coffee makers, and toasters all required magnet wire, fueling Essex’s rapid expansion and solidifying its position as an industry leader.

Magnet wire is essential in countless applications because of the varied types of insulation, known as enamel or wrapping, that provide a nearly endless combination of properties.

Just as George A. Jacobs transformed the industry by replacing cotton insulation with enamel over 100 years ago, new insulation technologies are constantly being developed and tested.

While Essex Brownell is not directly involved in the manufacturing process, as a distributor of Essex Solutions under the Superior Essex umbrella, we are dedicated to providing the best magnet wire products on the market to best serve our customers’ needs.

One of our most widely used enamels today is GP/MR-200, an evolution of the older Amide-Imide enamel. GP/MR-200 is a Polyester/Polyamideimide/Ester wax enamel that improves electrical insulation, heat resistance, and mechanical strength, making it ideal for hermetic applications like a refrigerator compressor.

This enamel is available in round wire (measured by gauge) and shaped wire (measured in inches like .125” x .250”).

The thickness of the enamel coating, known as the build, is standardized by NEMA (National Electrical Manufacturers Association) to ensure consistency across manufacturers. NEMA classifications for GP/MR-200 include:

MW 35-C for copper round wire

MW 35-A for aluminum round wire

MW 36-C for copper shaped wire

MW 36-A for aluminum shaped wire

Additionally, magnet wire has a thermal classification, indicating the maximum temperature the wire and insulation can withstand before degradation. GP/MR-200’s thermal ratings are:

200°C (392°F) over copper

220°C (428°F) over aluminum

Unlike enamel coatings, wrapped wire is exactly what it sounds like, insulation material is wrapped around the wire, similar to the cotton-wrapped magnet wire of the past.

The most common wrapped wire insulation we offer is DuPont’s Nomex®, an Aromatic Polyamide paper material known for its high-temperature resistance and inherent flame resistance. It can withstand 220°C (428°F) for copper and 240°C (464°F) for aluminum before degradation. When in contact with flames, it won’t melt, drip, or support combustion.

Nomex® is popular in the Energy market, which we’ll cover in a later installment.

Magnet wire is everywhere, even if we don’t always see it. It’s the driving force behind modern electronics, powering industries across the globe.

At Essex Brownell, we partner with premier manufacturers to deliver magnet wire solutions for all of our customers’ needs.

The future installments of this series will highlight magnet wire’s specific applications across the industries we serve. Part two will highlight applications for the Industrial market, so make sure you follow Essex Brownell on social media, so you don’t miss an installment of this series.

If you’re ready to order or need help finding the right magnet wire for your project, contact us and a member of our sales team would be happy to assist you.

Magnet wire is everywhere, even if we don’t always see it. It’s the driving force behind modern electronics, powering industries across the globe.

At Essex Brownell, we partner with premier manufacturers to deliver magnet wire solutions for all of our customers’ needs.

The future installments of this series will highlight magnet wire’s specific applications across the industries we serve. Part two will highlight applications for the Industrial market, so make sure you follow Essex Brownell on social media, so you don’t miss an installment of this series.

If you’re ready to order or need help finding the right magnet wire for your project, contact us and a member of our sales team would be happy to assist you.

___

Read the other posts in the series:

Industrial Applications for Magnet Wire

Energy Applications for Magnet Wire

Motor Repair Applications for Magnet Wire

Commercial and Residential Applications for Magnet Wire

Electronics Applications for Magnet Wire