Silicones Series: Gels and Encapsulants

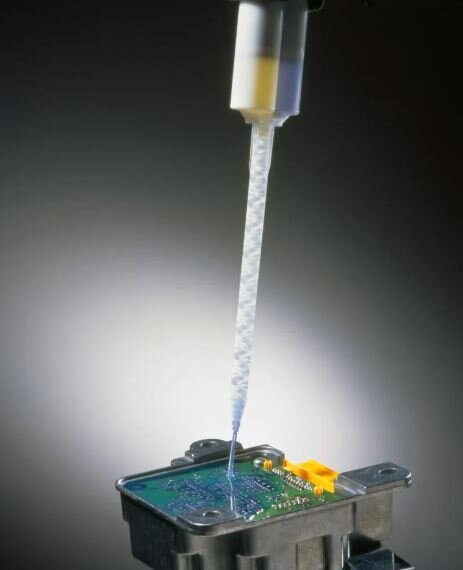

Gels and encapsulants are another product family from Dow that are designed to provide increased protection to PCB components. They are typically used when components on a PCB are taller than 200 microns, or have a very complicated landscape. Silicone gels and encapsulants offer the maximum protection available from mechanical stress caused by mismatched CTE or thermal cycling and extraordinary protection against shock and vibration – (think about an airbag sensor being activated by a pothole instead of by a collision) a silicone gel could be behind the sensor’s reliable performance. The selection of a gel or an encapsulant is driven by properties needed for a given application: if the application requires greater stress relief for sensitive components and will be contained within a sealed outer casing, a self-healing gel may be selected. If abrasion resistance is more important, then an encapsulant, while reworkable, will provide more protection with a generally harder surface.

The DOWSIL™ and SYLGARD™ gel product lines are categorized as either standard or specialized products, whereas specialized gels have expanded temperature ranges, are mechanically tougher than standard gels, or may be developed for specific markets or cure types. Final product selection is usually determined by (1) how much stress relief is required, (2) viscosity, and (3) working or cure time. With few “tough gel” exceptions, hardness is measured in grams of pressure vs. actual durometer measurements. Primers are not usually required since gels are tacky by nature but cleaning with one of the DOWSIL™ OS Series of cleaning products may improve adhesion and performance.

Standard gels are all variations of three basic products exhibiting a wide range of characteristics: DOWSIL™ EG-3000, SYLGARD™ 527 and SYLGARD™ 528. Most standard gels have a temperature range of -45⁰C to as high as 150⁰C. All standard gels, except for SYLGARD™ 535 and SYLGARD™ 537 are two-part systems. DOWSIL™ EG-3000 is a thicker viscosity, a two-part heat cured product designed to allow selective application on a board; SYLGARD™ 535 is a one-part product designed to perform similarly. SYLGARD™ 528 is one of the tougher standard gels, with an unexpected level of mechanical strength along with a long working time and extra adhesion. SYLGARD™ 537 takes this chemistry, makes it a single component material, and increases the mechanical strength and adhesion properties. Last, SYLGARD™ 527 has been an industry standard for use with delicate components and features a two-hour working time, heat or room temperature cure options, and low viscosity upon mixing, which allows for good flow around components. Derivatives of SYLGARD™ 527 include DOWSIL™ 3-4150 (faster cure) and DOWSIL™ 3-4154 (faster cure AND longer working time).

High/Low temperature gels are the extremists in the Dow gels portfolio. They take the major benefits of standard gels and expand the abilities of the gels to withstand extreme temperature ranges from a subarctic -80⁰C to an extra crispy 200⁰C. By way of example, DOWSIL™ EG-3810 gel is a one-part, clear gel that cures with heat applied in under 20 minutes. DOWSIL™ 3-6635 was developed to remain flexible, protecting components by keeping a continuous seal and coating down to -80⁰C.

Gels by nature are softer, more forgiving, and more flexible than encapsulants. However, there are times when a product needs to offer more protection than a gel without having to be totally enclosed in an outer housing. Enter the DOWSIL™ family of tough gels. Where most standard gels’ hardness factors do not register on the Durometer scale – tough gels register from 220 grams up to 60 shore 00. All tough gels feature a two part cure system and are heat cured. They vary greatly in pot life with the original DOWSIL™ 3-4207 gelling in 7 minutes to the DOWSIL™ 3-4241 providing a longer working time of up to 1 hour. Both of these products are UL 94 listed.

Encapsulants generally offer similar benefits as gels, but often provide more abrasion resistance as well as mechanical stress protection to delicate components. Durometer measurements for encapsulants range from Shore 00 20 to Shore A 65. The DOWSIL™ and SYLGARD™ standard encapsulants require the use of a primer such as DOWSIL™ 1200 OS Primer to promote proper adhesion but primerless options are available. All of Dow’s encapsulants are two-part systems with easy to mix ratios of either 1:1 or 10:1 and may be black, gray or clear in color.

Essex Brownell carries a broad range of Dow encapsulants. SYLGARD™ 170, SYLGARD™ 160 and SYLGARD™ 182 are longstanding industry workhorses each with unique properties that conform to UL94 in the standard encapsulants family. Dow’s SYLGARD™ 170 also conforms to MIL-PRF-2368F as well as EN45545-5-2. This product has moderate thermal conductivity, and cures at room temperature in 24 hours, or heat may be applied to reduce cure time to 10 minutes if needed. If a higher thermal conductivity factor is specified to allow heat to dissipate away from the encapsulated component, SYLGARD™ 160 may be selected. This also cures at room temperature in 24 hours or may be heat cured in as little as 4 minutes. While SYLGARD™ 170 and SYLGARD™ 160 are dark gray or black in color, the last option, SYLGARD™ 182 is clear with a long working time and room temperature cure that can take up to 14 days. Of course, the cure cycle can be made significantly shorter (to as little as 20 minutes) with the application of heat. A fast cure option for all three of these outstanding products is also available if heat cure is not possible. Other standard encapsulants are suited for high output automated operations (see DOWSIL™ CN 8760, DOWSIL™ CN 8760 E and DOWSIL™ EE 1010). If efficiency in operations is a key metric, removing the primer application step from the manufacturing process may improve output and provide cost savings. SYLGARD™ 567 is black in color, features simple 1:1 mix ratios, flows well into small, complex spaces and demonstrates a fast cure time under heat at 15 minutes.

Take the Next Step

With all of the helpful applications of gels and encapsulants, go ahead and contact an Essex Brownell expert for more information or to place an order

HERE.

Next up is Silicones Series, Part III. Stay tuned!