Silicones Series: Conformal Coatings

Silicones are used in applications as complicated as satellites and e-mobility modules or as simple as the casings around our cell phones and seals for our windows. They offer unmatched protection for sensitive components against impacts, vibrations, dust, moisture, and extreme changes in temperature.

While silicones may appear to be the highest price product solution, as a product family, they offer several performance and processing advantages over organic materials such as urethanes and epoxies. Silicones can help to reduce or eliminate special handling precautions required for organics related to their toxicity. Unlike urethanes, they do not require the costly use of ovens to thoroughly dry components before processing. Unlike epoxies, silicones impose no concerns about exotherms during cure. No exhaust is necessary, fire hazards are mitigated, and no special transportation precautions are needed. Essex Brownell is proud to be a national master distributor for Dow silicone products including transformer fluid, gels and encapsulants, conformal coatings, sealants, and adhesives as well as thermal management materials.

Conformal Coatings

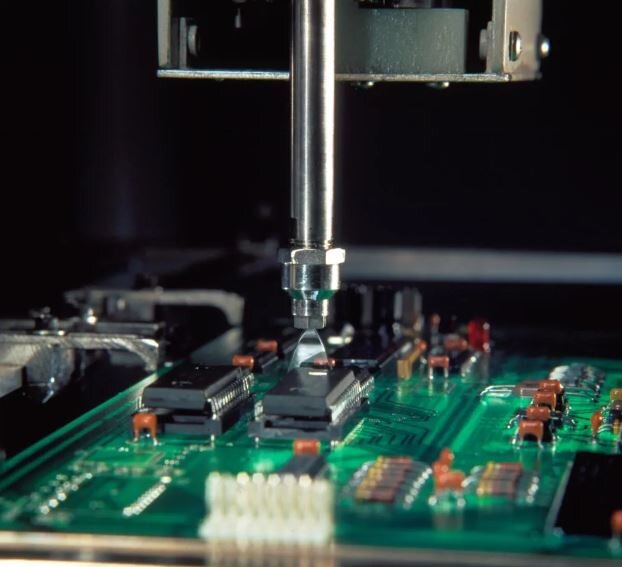

Conformal coatings are one of many ways silicone products are used to protect electronic components from environmental stressors, in particular, dust, moisture, and extreme temperatures. Conformal coatings prevent exposure to contaminants but also allow any trapped moisture to escape. In addition to protection against environmental hazards, properly applied conformal coatings allow tighter component spacing on PCB’s, (resulting in the potential to reduce board size and the use of more complex enclosures) as well as a reduction in weight per design and they increase the useful life of the end product.

The DOWSIL™ line brings thermal stability with temperature tolerances ranging from -50⁰C to as high as 200⁰C, a broad range of viscosities and cure types to match different manufacturing processes and production output goals, as well as a wide range of hardness options to meet an application’s stress/abrasion requirements. Low viscosity products like DOWSIL™ 3-1965 are suitable for spraying an entire assembly, whereas higher viscosity products such as DOWSIL™ 3-1944 can be used for situations where control and precision are of utmost importance (such as solder joint coverage). If the manufacturing process requires “set it and forget it,” then a quick curing room temperature moisture cure (also known as RTV cure) such as DOWSIL™ 3-1953 that can be tack free in under 10 minutes, may be a good option. Others, like DOWSIL™ HC-2100 take longer and are better suited to flow over larger or more complex boards. Heat cure (or “command cure”) products, like DOWSIL™ 1-4105, are also available as part of the DOWSIL™ line for high output operations that demand full cure within minutes.

All the aforementioned conformal coatings are solventless with shore hardness ranging from under 15A to 40 shore A and are designed to reduce mechanical stress on smaller, delicate components. However, if abrasion resistance is critical, then the DOWSIL™ line does have a number of solvent based chemistries like DOWSIL™ 1-2577 and DOWSIL™ 1-2620 that take advantage of silicone’s innate advantages, while offering a harder cured end result for extra protection from abrasion. It is recommended that surfaces to which conformal coatings are being applied are cleaned by use of one of the DOWSIL™ OS Series of cleaning products.

Take the Next Step

Essex Brownell's elite selection of conformal coatings are excellent solutions to protect electronic components. Contact an Essex Brownell expert for more information or to place an order

HERE. We'll help guide you to a solution that fits your needs.

Be on the lookout for Silicones Series, Part II coming soon!